Index

Test machines

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test ancillaries

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measurement

|

|

|

|

|

Production

|

|

Services

|

|

|

|

|

|

|

|

Miscellaneous

|

|

|

|

|

|

|

|

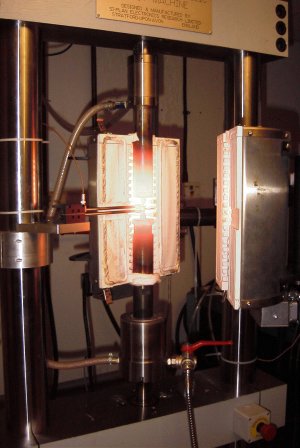

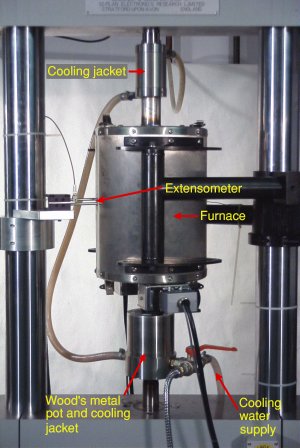

Three zone furnace and controller

|

Description

Application Ideal for medium and high temperature alloy material testing. Construction Electrical supply Operating Temperature |

|

|

Furnace Dimensions

|

|

|

either local (Eurotherm) or remote via a 0 - 10V external input which may be |

Updated 20 April 2005