Index

Test machines

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test ancillaries

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measurement

|

|

|

|

|

Production

|

|

Services

|

|

|

|

|

|

|

|

Miscellaneous

|

|

|

|

|

|

|

|

Breathing Simulators

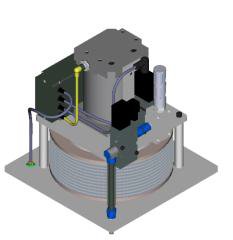

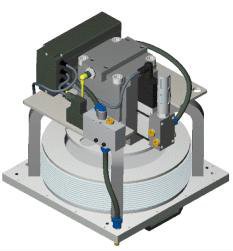

Si-Plan Electronics Research Ltd manufactures breathing simulators in two sizes:| The '300' Breathing Simulator | The '625' Breathing Simulator | |

|---|---|---|

|

|

|

| Maximum tidal volume of 3 litres | Maximum tidal volume of 6.25 litres | |

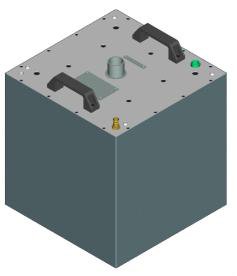

| Illustrated with case removed | Illustrated with case removed |

| Complete Breathing Simulator |

|---|

| enclosed in case |

|

The current breathing simulator technology is available in two sizes: the '625' has a maximum tidal volume of 6.25 litres and the '300' has a maximum tidal volume of 3 litres.

Each breathing simulator is a self-contained unit controlled and monitored by the RS232 serial port of a PC.

- Electrical supply required: 110/230 volts AC.

- Compressed air supply required: between 5 and 10 bar.

(The figures quoted below in 'System Description and Specification' are based on an air supply pressure of 6 bar.)

The Breathing Simulator is also available in a version with remote power supply and control systems for special applications, for example oxygen-rich atmospheres.

- Maximum voltage in the special-version breathing simulator: 24 volts DC.

- Compressed air supply required: between 5 and 10 bar.

(The figures quoted below in 'System Description and Specification' are based on an air supply pressure of 6 bar.)

The serial link with the PC enables the user to:

- load breathing waveforms;

- view flow profiles generated by the operation of the simulator;

- initiate start and stop;

- record data in CSV format.

Modes of use

- Running as an independent unit

- to simulate a pilot, fire-fighter or diver to evaluate breathing support systems;

- to simulate patient breathing profiles (for medical and pharmaceutical applications).

- Two breathing simulators can be run independently with phased or beating waveforms to simulate two breathers being sustained by one breathing support system.

- Two breathing simulators can be run with phased waveforms to evaluate a breathing support system in conjunction with g-suit pressure system, eg pilot.

- Two sets of two breathing simulators can be run in a linked mode to simulate two breathers with g-suits breathing on the same life support system.

System Description and Specification

The Breathing Simulator system consists of a stainless steel bellows driven by a servo-pneumatic system. The servo pneumatic system comprises an ultra low-friction, purpose builtpneumatic actuators with integral displacement/velocity transducer (analogous to volume and flow) and manifold-mounted servo valve. The servo control loop works in displacement control and is implemented on a dedicated RISC processor, which also stores flow breathing profiles. The RISC processor performs the necessary mathematical integration to convert the flow profiles into balanced volume waveforms, implementing the servo-control algorithm.

The system features a built-in air on-off valve which enables an automatic shutdown after a preset period to conserve the air supply. A clean, dry air supply is required which may be from bottled air or from a compressor.

| Characteristic | '300' Simulator | '625' Simulator |

|---|---|---|

| Maximum tidal volume | 3 litres | 6.25 litres |

| Minimum tidal volume | 50 millilitres | 100 millilitres |

| Minimum breaths per minute | 5 | 5 |

| Maximum breaths per minute | 100 | 60 |

| Maximum minute volume | 180 litres per minute | 375 litres per minute |

| Minimum minute volume | 0.25 litres per minute | 0.5 litres per minute |

| Maximum flow: | ||

| ...step input to bellows position | 1000 litres/minute | 1200 litres per minute |

| ...sinusoidal wave at 1 hertz | 500 litres/minute | 800 litres per minute |

| ...square wave at 1 hertz | 500 litres/minute | 800 litres per minute |

| Maximum rate of change of flow (gas acceleration) | *Up to 600 l/sec2 | **Up to 444 l/sec2 |

| Normal working pressure of bellows | Up to 10 kPa.g | Up to 10 kPa.g |

| Maximum differential bellows pressure | 40 kPa.g | 40 kPa.g |

| Height (including feet and handles) | 410 mm | 410 mm |

| Width | 355 mm | 355 mm |

| Depth | 355 mm | 355 mm |

| Weight | 40 kg | 40 kg |

*0 to 800 l/min in 20 milliseconds.

**0 to 800 l/min in 30 milliseconds.

Figures quoted above are based on an air supply pressure of 6 bar.

Operating conditions

The Breathing Simulator bellow assemblies are designed to operate under the following conditions

- Ambient pressure range 2 to 1200 mbar (abs);

- Ambient temperature range: minus 5 to plus 50 degrees centigrade;

- Ambient humidity range up to 90% relative humidity.

Software package

The software package was originally written to run on an Acorn RISC PC. It has been re-written to operate on Windows 95 and Windows NT.

The computer operating system enables:

- Breathing profiles to be loaded in CSV format

- Downloading and storage of breathing profiles in the RISC processor within the breathing simulator.

- Setting of parameters for each breathing machine:

- select breath profiles;

- set breathing rate; } set any 2 parameters

- set tidal volume; } the third is calculated

- set minute volume; } and the value displayed.

- set number of cycles.

- set phase angle (in linked simulators);

- Viewing of flow profiles generated by the operation of the simulator;

- Start and stop control;

- Recording data in CSV format.

- Control of up to four (linked) breathing machines.

- Graphic dynamic display of bellows position.

- Static display of actual volume/flow waveform (refreshed periodically).

Optional software packages

- Profile generation software enables breathing profiles to be viewed, created, edited and exported for loading into the simulator control software. CSV files can be imported for editing.

- Sequencing software allows a sequence of varying profiles to be strung together to recreate the changes in breathing patterns of a subject in a real-life situation. The sequence is executed automatically by the software program. Sequences can be saved, recalled at a later date, copied and edited.

Generation of breathing profiles

This can be:

- customer defined/supplied in CSV format;

- written or generated in the optional profile generation software described above (in CSV format);

- recorded from living subjects by optional Si-Plan pneumatach system.

PC requirements

Suggested specification:- 1 x Intel Pentium III 450 MHz PC running Windows NT;

- 3.5" floppy disc drive;

- 32Mb SDRAM (minimum);

- Video card: 8Mb video ram;

- 24 speed CDROM drive;

- 11.5 gigabyte UDMA hard disc drive;

- 17" colour monitor (1280 x 1024);

- Keyboard and mouse;

Optional:

- Ethernet Card;

- Data backup, for example:

- ZIP Drive: 100 megabyte;

- Travan tape: 8 gigabyte;

- Rewritable CD 640 megabyte.

Si-Plan is able to quote for the supply of a suitable computer.

All prices are available on application.

Updated 20 April 2005