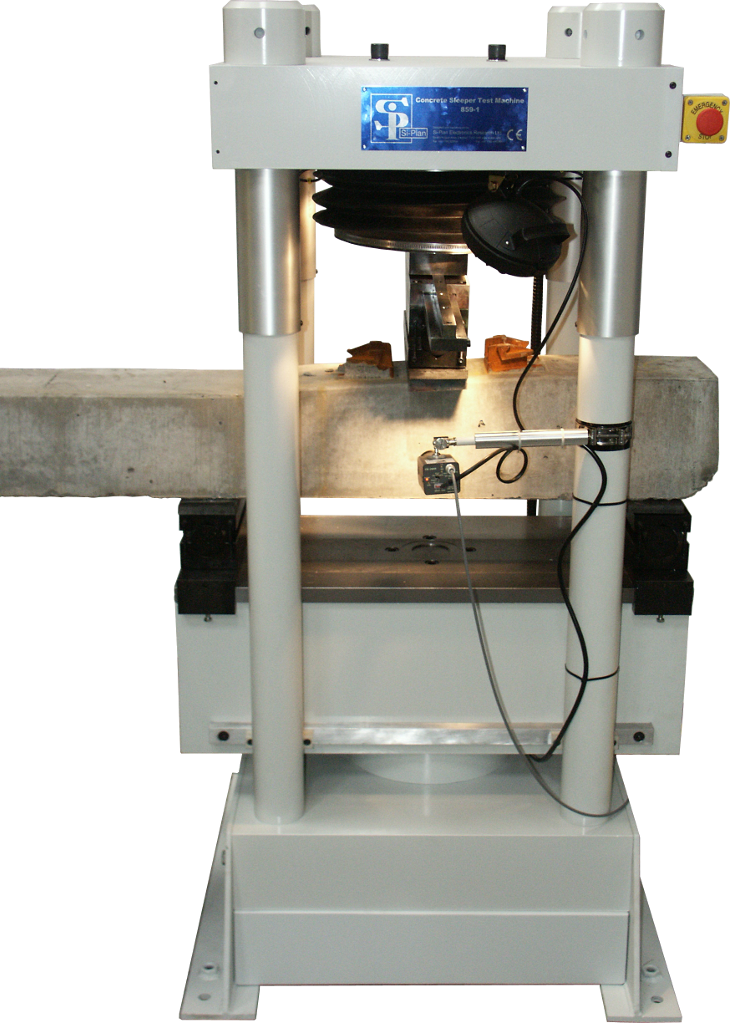

Railway sleeper tesing to BS EN 13230-2

- 4 pillars with integral strain gauging for resilient and accurate performance. Load is measured by adding together the 4 load cells (one per column) thus ensuring accurate load measurement throughout the life of the machine.

- Fixed top crosshead with ball seat mounting top platen ensuring even load distribution

- Fixed base mounting actuator assembly

- Test set up, operation, control, display and data logging is via a software programme running in Windows on a desktop PC with mouse and keyboard. The programme is part of the software suite of the 1085 Series Servo-controller and Data Acquisition Unit.

- Timings for load ramp and dwell can be defined by the operator.

- A remote pendant enables the operator to pause the test when a crack is identified and record the load.

- 1000kN servo-hydraulic with 50mm stroke.

- Rail seat positive load test

- Positive and negative centre load tests