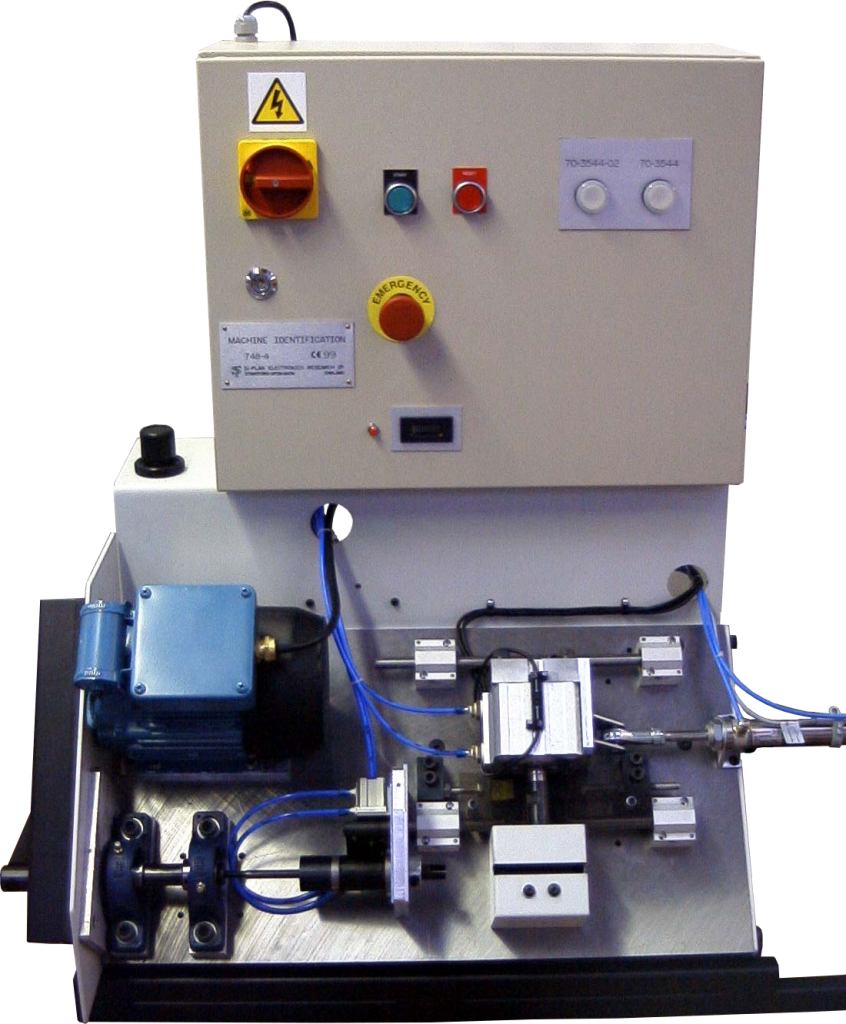

Spin-on Production Machine

Automotive Component Production

- The machine spins snap-in fittings onto flexible

plastic tube/wire assemblies, creating a friction weld. - Products are used in

• automotive seats (hinge-forward facility)

• throttle/clutch cables for lawnmowers

• central locking systems. - Designed for high output / short cycle time – up to

1000 units/hour. - PLC controlled.

- Interchangeable adaptors match a variety of fittings.

- Colour sensor to ensure operator uses correct pieces.

- Machine cycle initiated by operator via foot switch.

- Operates from 230VAC and compressed air at 6 bar.

12 machines supplied, including 100% quality

inspection stations for working length and tensile

strength of assemblies.