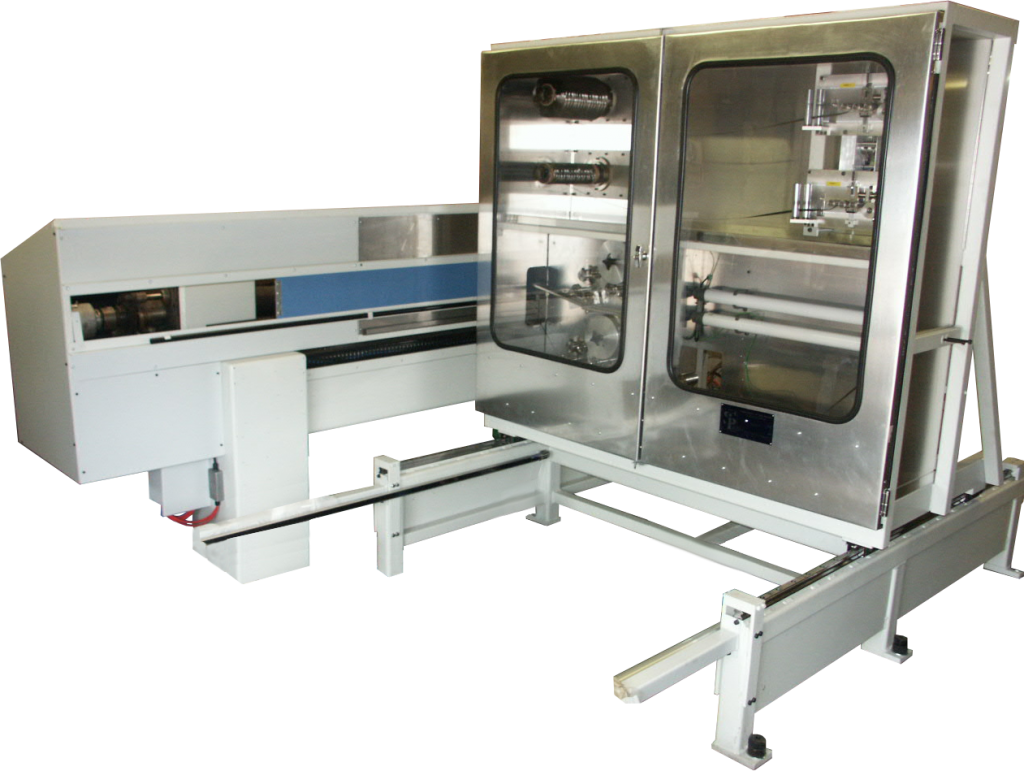

2 Axis Carbon Fibre Winder

A machine for manufacturing wound carbon fibre parts. A heated mandrel rotates and draws 2 fibres over rollers and through temperature controlled resin baths.

A two stage tensioning process applies a pre tension as the fibre is wound off its spool. After passing through the resin a final tension is applied before being wound onto the part.

- Overall systems control and programming via Siemens machine control unit with control of:

- mandrel speed & angular position

- mandrel temperature

- fibre winding cabinet position

- resin bath temperature x2

- Real time servo control via embedded Si-Plan digital controller of:

- 2 fibre tows with:

- programmable fibre pre and final tension x2

- programmable speed

- 2 fibre tows with: