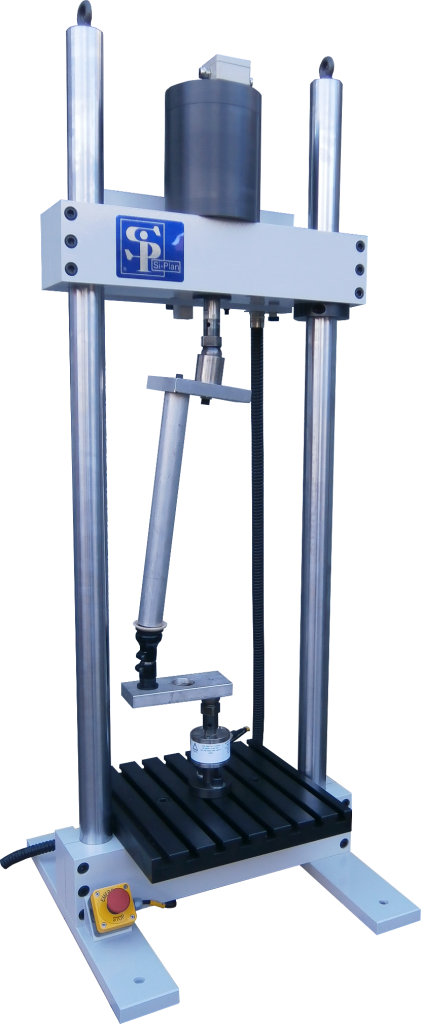

Servo-pneumatic fatigue test machine

2-10kN bench top system

A standard range of machines where the specifications can be adjusted to meet customer requirements.

Frame

- Rated up to 25 kN tension & compression.

- Fixed bottom crosshead.

- Movable top crosshead clamped by pinch bolts.

- Actuator mounted on top cross head.

- Two chromed solid steel columns.

- Top and bottom crosshead and feet powder-coated (RAL7035)

- Space between columns: 405mm

- Standard column length: 1200mm.(650mm maximum daylight space).

- Different column lengths available on request.

- Weight, including actuator: 220kg

Actuator

- Low friction grade pneumatic actuator.

- Mounted on crosshead.

- Capacity options (shown as the static rating for 7 bar air supply):

- 2kN

- 5kN

- 10kN

- 15kN

- 20kN

- 25kN

- Standard stroke options:

- 50mm

- 100mm

Load cell

- The fatigue-rated load cell can be mounted on either the top or bottom crosshead.

Controller

Si-Plan Digital Control and Data Acquisition System with a Windows® PC which is utilised to provide the user interface for machine control and data capture.

Pneumatic supply

The compressed air supply for the actuator should be:

- Between 5 and 10 bar.

- At room temperature.

- Free of oil contamination.

- Filtered to 5 micron maximum particle size.

Advantages of pneumatic

- High reliability – low maintenance.

- Major price advantage over servo-hydraulic and screw-thread machines.

- Little or no heat generated.

- No fire risk.

- Runs from filtered workshop air or bottled air.

- Low inertia.

- Inherent predictable stall thrusts.

Accessories

Accessory options

- Clip gauge.

- Grips

- Ball nut & ball cup.

- Flat and round.

- Wood’s metal pot.

400mm2 slotted tooling plate to suit M12 T-nuts.