Servo hydraulic actuators use pressurised hydraulic oil acting on a piston to create movement and force.

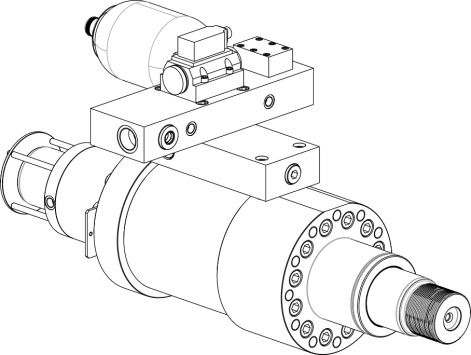

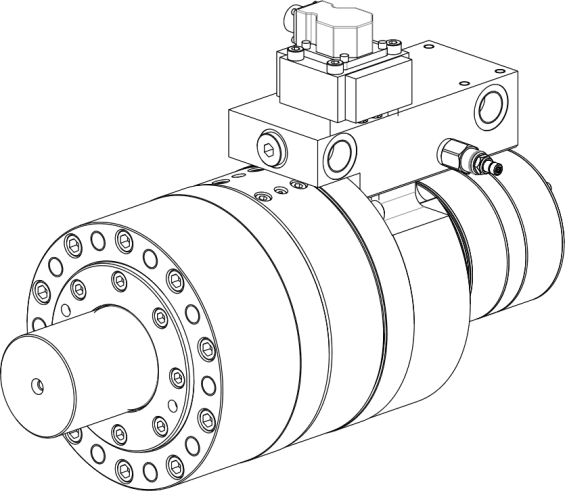

Usual configurations are single ended and double ended. This refers to whether there is a rod protruding from one end or both ends of the actuator. Fatigue rated actuators are normally double ended while static rated actuators can in some cases be single ended. They can benefit from lower manufacturing costs associated with only one rod to seal and a shorter, simpler piston rod to manufacture.

Servo hydraulic actuators can be either sealed or seal-less. In general sealless actuators are more expensive to manufacture but have a much longer life and the control resolution is better allowing for finer control in strain and through zero conditions.

Si-Plan has proven designs for both sealed and sealless linear and rotary hydraulic actuators and hydraulic cylinders. Internal actuators bearings prevent contact between the piston / rod assembly and the housing. These bearings can typically be phosphor bronze, polymer or hydrostatic. All types have their merits and Si-Plan builds actuators using all these technologies.

When selecting the best engineering solution the application is considered and the appropriate actuator design offered, taking into consideration the required design life, performance and budget constraints.