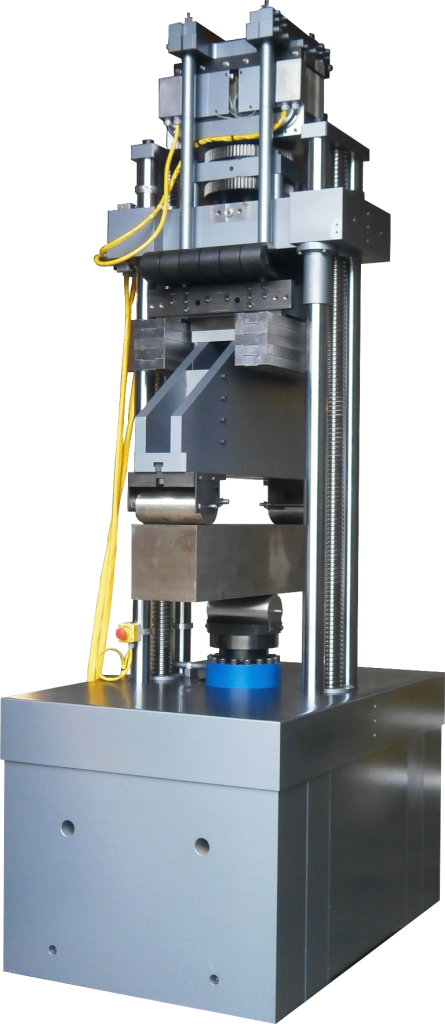

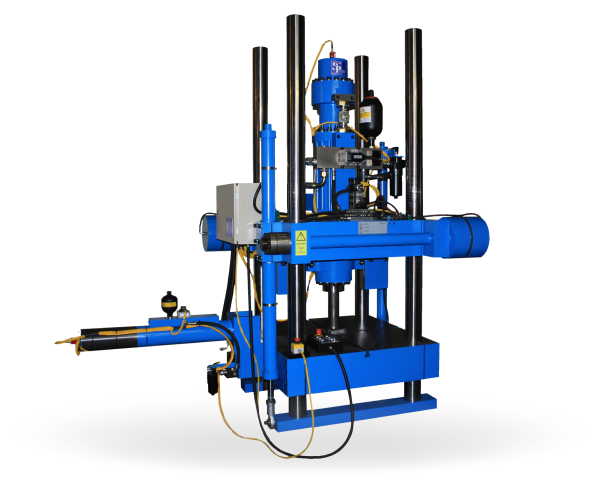

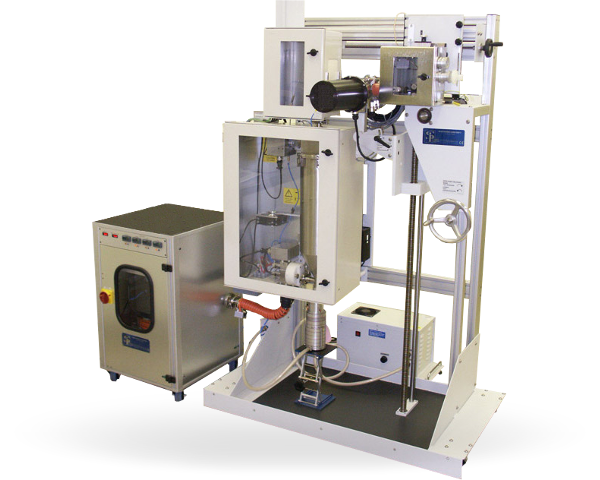

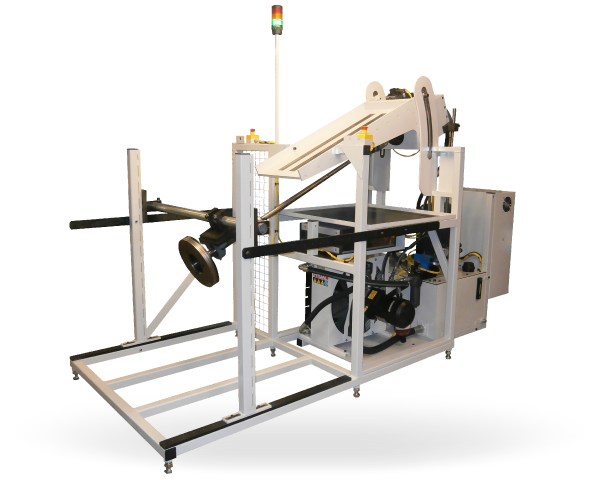

Si-Plan designs and builds test and manufacturing machines

We are a solution provider to your engineering requirements.

Our work often involves research, design and development to provide project solutions to a wide range of sectors and disciplines.

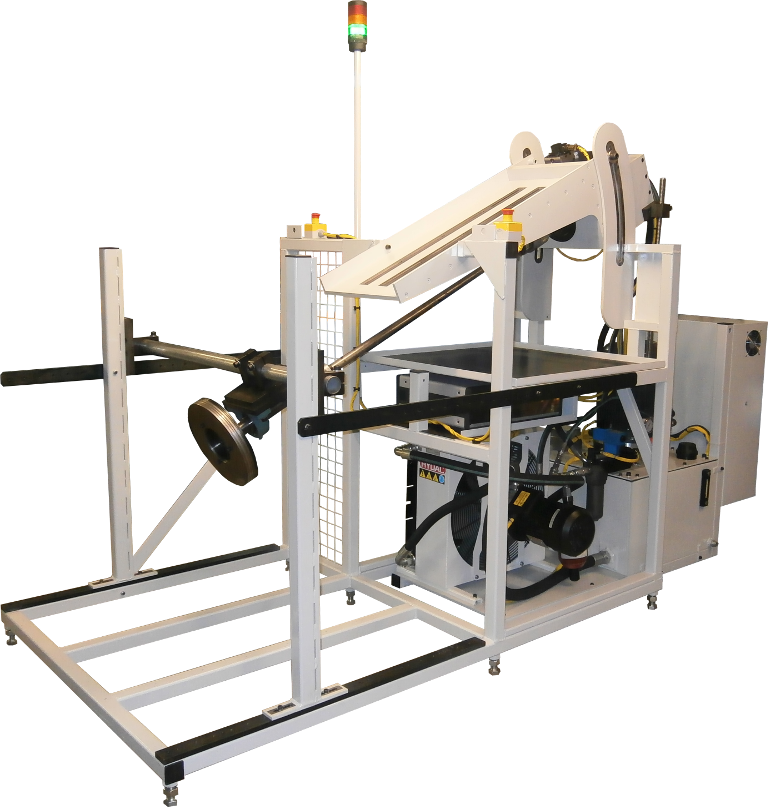

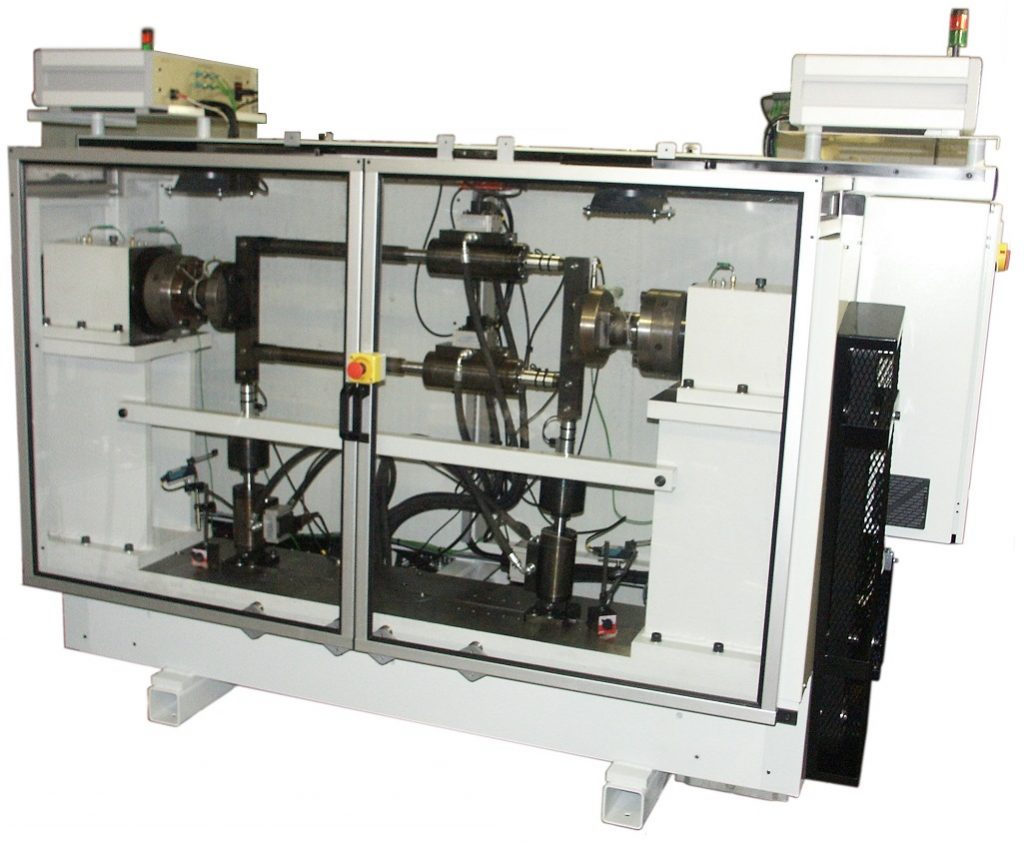

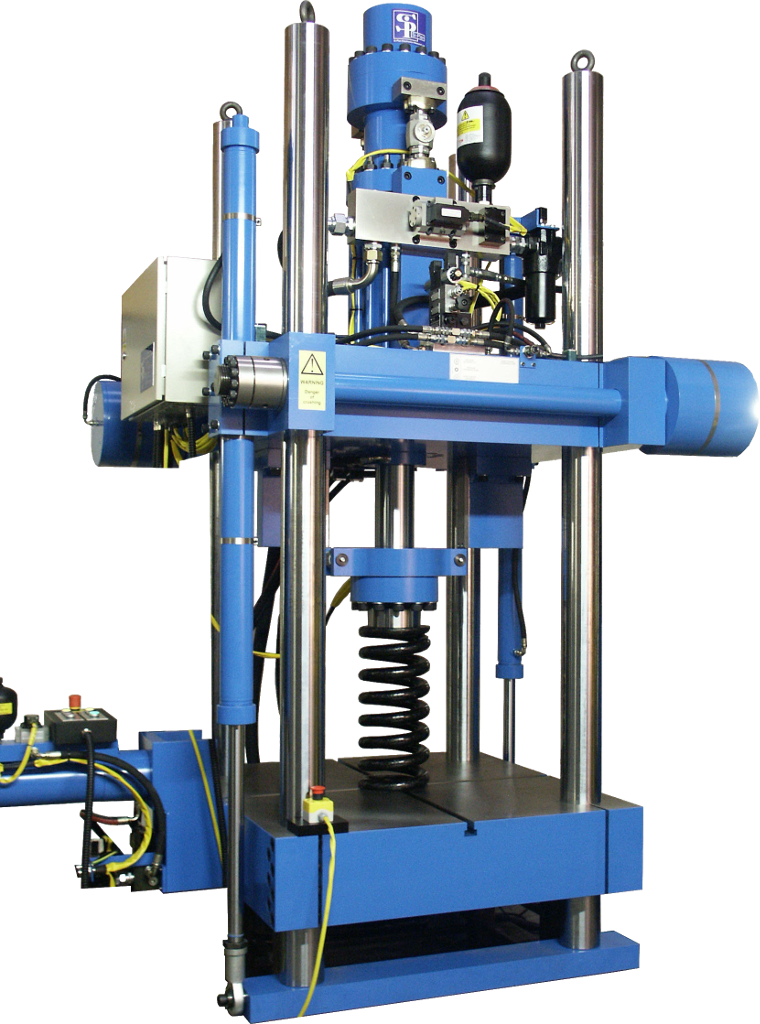

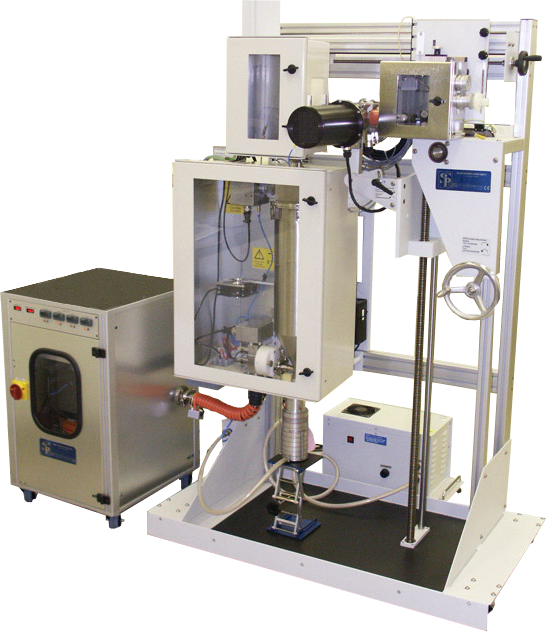

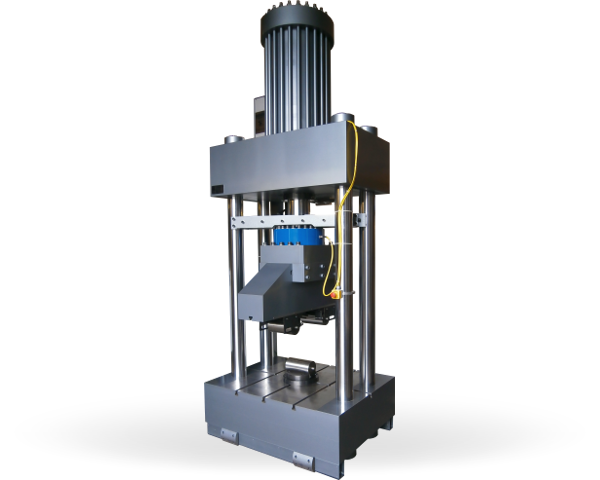

Example Machines

Experience in understanding customer requirements…

The team has many years of experience in understanding customer requirements, then selecting the relevant measurement, control and data collection techniques and combining them with the appropriate prime mover technology to embody a solution.

A typical project results in the supply of a machine and / or control system.

Si-Plan also has a history of applying its research and development expertise in designing a component or product to meet a specific requirement then undertaking the ongoing manufacturing requirements.

We are a test rig and production rig manufacturer with a focus on bespoke design, however we do have a range of standard machines which suit customers needs. We also offer component assembly solutions and production line test systems.

Project application areas include

- Design qualification testing

- Production acceptance testing

- Laboratory test

- Manufacturing machines