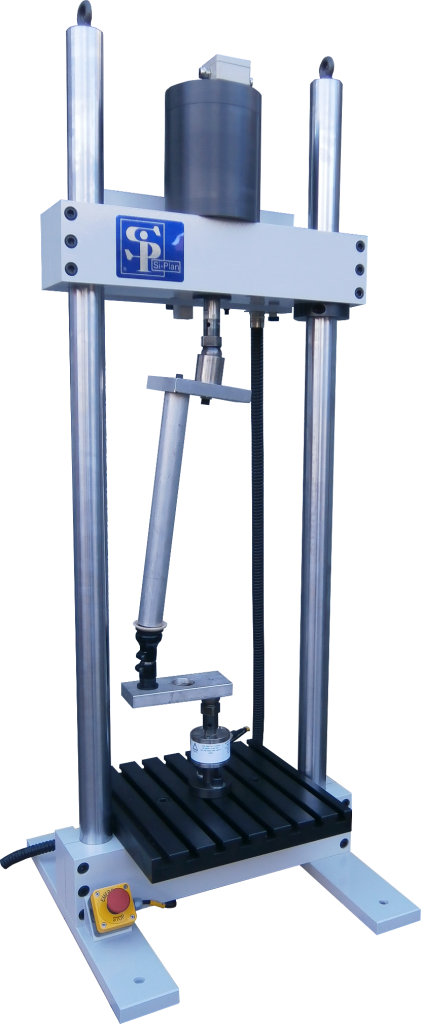

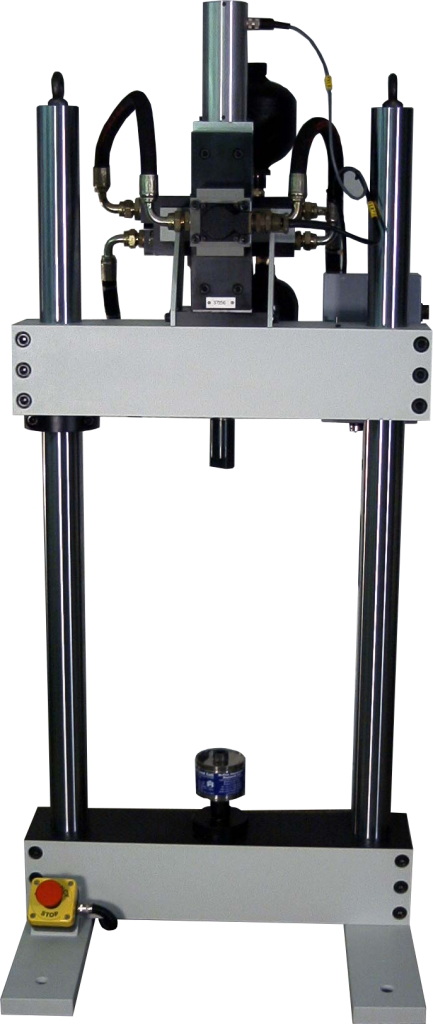

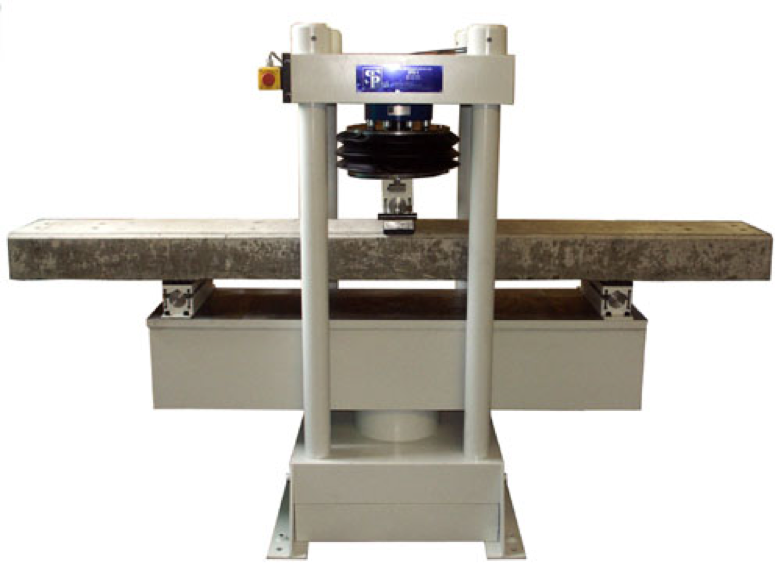

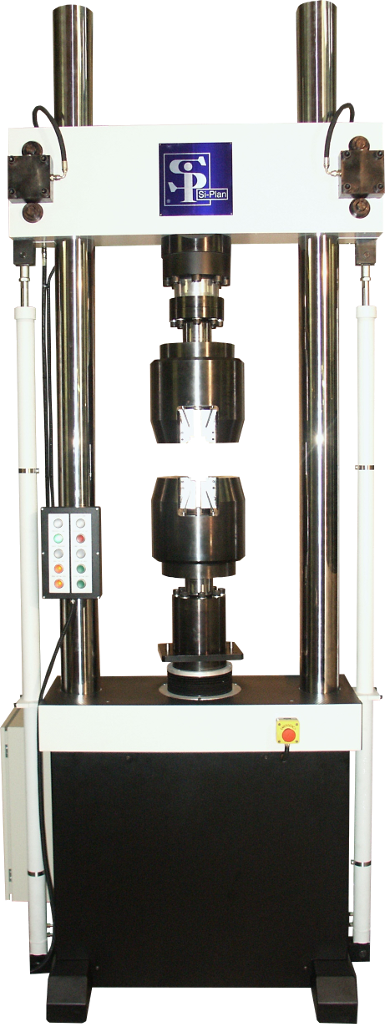

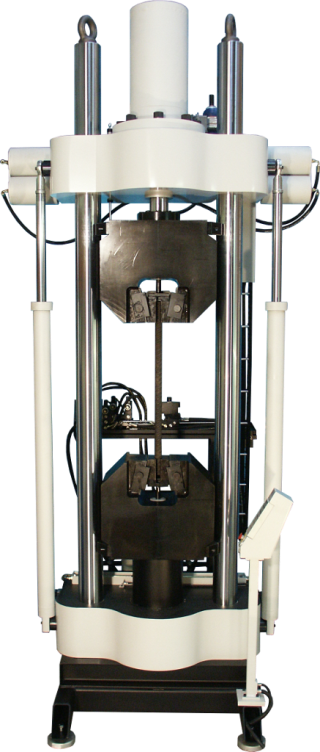

Universal Test Machines

Servo hydraulic test machines use pressurised hydraulic oil acting on a piston to create movement and force.

Hydraulic oil is controlled or metered by a servo valve. Differential pressure across a piston causes it to move. When it touches something this translates into a force. Servo valves are essentially precision high response flow control valves and can be either current or voltage controlled depending on the design. The Si-Plan digital servo controller and data acquisition unit is capable of interfacing to either. A control algorithm compares the demanded value to the feedback signal from a transducer and feeds this into the control valve drive circuitry. The transducer can be for example, a loadcell for force measurement or an LVDT for displacement measurement. Test machine transducers are often incorporated into actuator assemblies. Servo hydraulic actuators or cylinders come in many configurations and sizes. They are often referred to as the prime mover in the servo hydraulic system.